Top-level innovative engineering & construction

Our engineering team is working on an impressive project in the United States. There, we are building an innovative greenhouse intended for growing salad. Tuur, Project Manager Technical Equipment, is looking after the coordination and execution of all technical aspects at high level.

He is proud to tell you more about it, but before we do, let us show you with the video below how sophisticated the engineering is approached.

Who is the client?

North Country Growers, based in the state of New Hampshire (US), located between New York and Canada is our contractor.

The firm's mission is to optimise food and energy systems.

Among other things, they design high-quality, energy-efficient greenhouses specifically designed to provide optimal growing conditions for plants, while optimising energy consumption and reducing environmental impact.

How did the client come to work together with us?

The greenhouses developed by and for Northland Country Growers typically feature advanced systems for temperature control, humidity regulation, and lighting, all of which are essential for creating the ideal growth environment for various types of crops. Additionally, these greenhouses often incorporate sustainable features such as rainwater harvesting, energy-efficient lighting, and renewable energy systems.

Hedafor is a knowledge centre for such complex situations. We ensure that the construction is tailored to all available technologies and coordinate them, resulting in an optimal and efficient building solution.

So, there's no need to look far to understand why they enjoy working with us.

Can you tell us more about the current project?

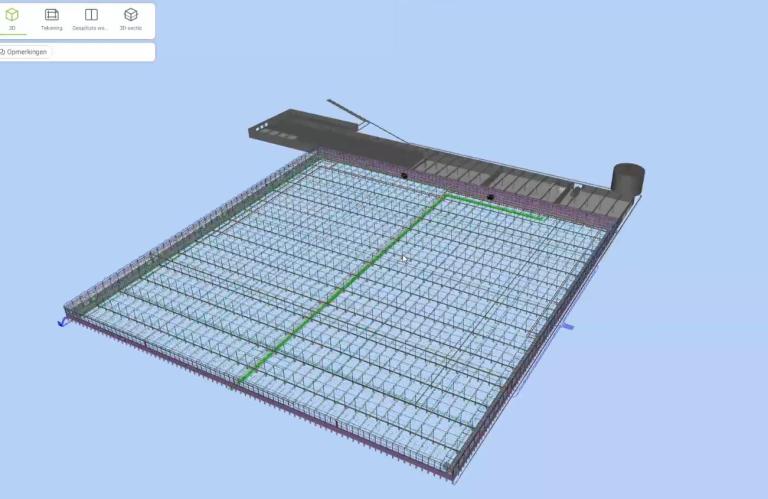

In Berlin, New Hampshire, we are building a large production greenhouse measuring 180 x 180 meters, which totals over 32,000 square meters in area. On the north side, there will be a warehouse dedicated to water treatment, heating facilities, and handling. It will also house the complete for heat distribution equipment for the greenhouse. It is a fully turnkey project where we provide the foundations, structure, and technical components.

The greenhouse is designed to grow lettuce, using hydroponics.

So the engineering is quite complex?

The project follows a trajectory starting with coordination, followed by concept, engineering, production, assembly, and finally, the service we provide.

The entire process is well-structured and presents a fine challenge that we enjoy taking on with our team.

Jens is Project Manager; Dominique works out the complete greenhouse construction; Sander mainly deals with the 3D design work of the structure, as well as detailed production drawings; and Aart is our Chief Engineer, technically responsible. He also ensures everything progresses well and ensures the availability of colleagues. I myself am in direct contact with both the client and subcontractors for the techniques.

Fortunately, we don't have to do everything on our own and can rely on our subcontractors.

Who are the different parties involved in the collaboration?

- Deforche Construction Group is the main contractor. In addition to full coordination, we are also taking care of the heating installation.

- For the water technology and electrical installation, we call on Tebarex from Lier.

- The company Luiten is responsible for the screening.

- Dryhydroponics supply the deep float basins used for growing the lettuce.

What is the current status of the project?

The engineering is in full swing and progressing smoothly. The greenhouse construction is fully completed and the technical installation have also progressed significantly!

Screening

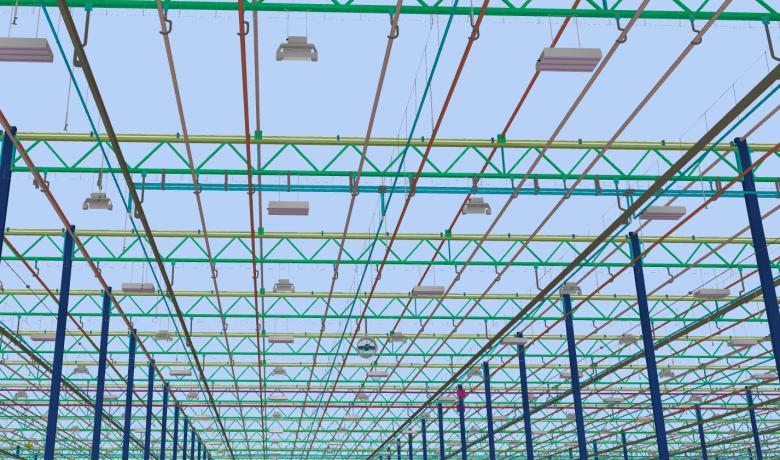

Our subcontractor, Luiten Greenhouses, takes care of the shading. The shading system is of high quality and meets the highest standards. All components were meticulously integrated into the new greenhouse. The screens are energy-efficient and will contribute to optimal cultivation results.

Could you proice more specific details about the heating system?

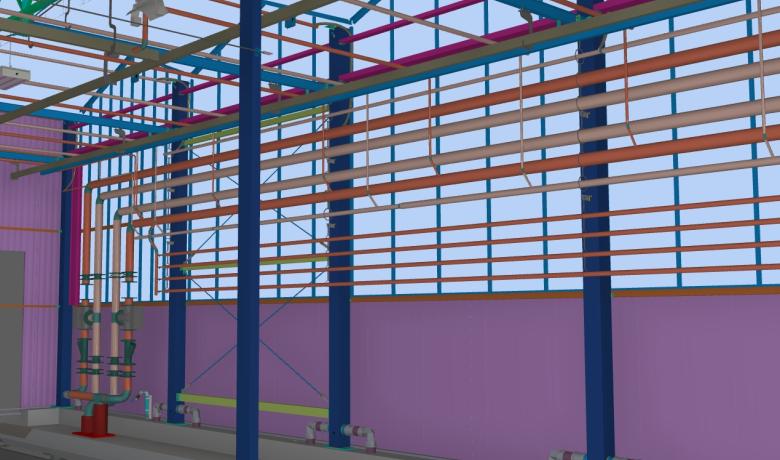

The heating system in the greenhouse is nearly complete, and Valo Greenhouse Heating has done an excellent job. Before the greenhouse was constructed, the underground heating pipes had to be welded, insulated, and assembled. In addition to the greenhouse installation, there is the boiler room located in a separate shed. The very latest techniques were applied here, taking into account environmental regulations and energy conservation.

Two CHP units (Combined Heat and Power), or WKKs (Warmtekrachtkoppelingen), were installed to simultaneously generate electricity and heat. The use of flue gas filters and the recovery of CO2 from the flue gases reduce the emission of harmful substances, and the recovered CO2 can be reused to stimulate plant growth. This not only ensures good energy efficiency but also aligns with the concept of a circular economy, which our customer considers crucial.

VL Greenhouse Services, a local company we collaborate with, is currently working in the boiler room and installing the buffer tank.

The boiler, with a capacity of 12.60 MW and a weight of over 28 tons, has been brought into the building. This boiler, along with the CHP units, is intended to heat the two greenhouses. Its enormous capacity allows for the rapid generation of sufficient heat.

Can you tell a little more about the water-technical installation?

The cooperation with our subcontractors Tebarex and Dry Hydroponics has been pleasant.

The greenhouse will have a total of 15 water basins, each measuring 170x12 metres. The lettuce is seeded in trays floating on the water of the basins. From seed to full-grown plants, the lettuce grows in this water. To support their growth, nutrients are added to the water. The salad is moved from one basin to another through an ingenious waterway system (you can think of it as log flumes in an amusement park 😉).

In the adjacent warehouse, the lettuce is harvested and packaged for sale.

Onderhoudsshuttle

Deze is volledig gemotoriseerd, toch wel top! Op deze manier zal de installatie na voltooiing gemakkelijk toegankelijk zijn voor inspectie en onderhoud.

What about the technical installations?

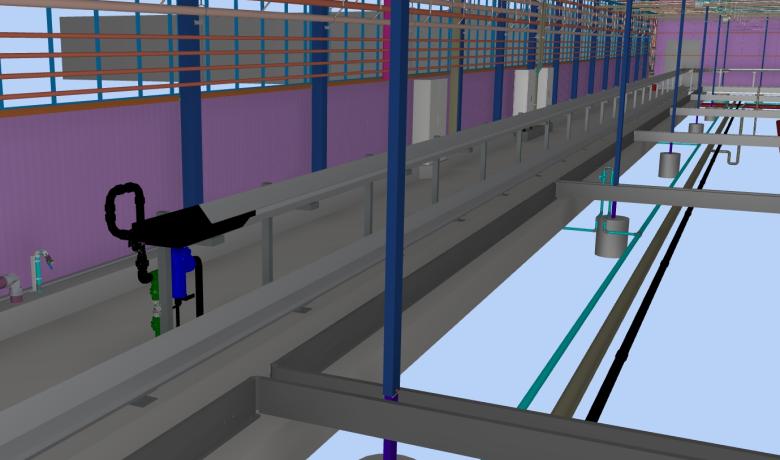

After the construction phase, the installation of the technical systems begins. In parallel, work will be done on installing the screening, grow lights, heating, irrigation and electrical installation. In the final phase, the site will be levelled and the ponds will come in.

By the beginning of next year, the greenhouse will be fully operational.

How do you ensure good coordination between the subcontractors?

A weekly (teams) meeting ensures that everyone stays involved in the project.

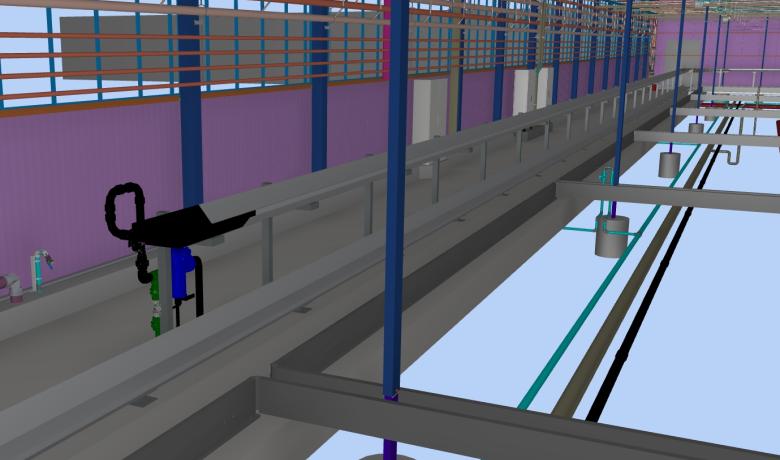

We utilize BIM software that allows us to collaborate in real-time on the design. All design data and drawings from the various parties are merged into one central BIM viewer. In doing so, the software is used to organise and coordinate the various installations and any clashes or conflicts in the designs can be detected and resolved.

As a user, you can explore the building through a virtual tour, moving through different rooms and floors. This gives a realistic picture of the actual building project, including the planned technical installations.

Frederick, our site supervisor, coordinates all activities on the construction site. He serves as the direct point of contact on-site for our subcontractors and the client.

How is the communication between the company and the customer?

It's going well! Weekly meetings bring tranquility and commitment.

By showing them our drawing and allowing the customer to virtually walk through their new conservatory, they are fully informed about the progress and are truly engaged.

We also regularly send photos and we feel that this is appreciated by our customer.

Now that Frederick is on-site, and the client observes that everything is progressing well, it is turning into a pleasant construction site that both the client and we will be proud of in the end.